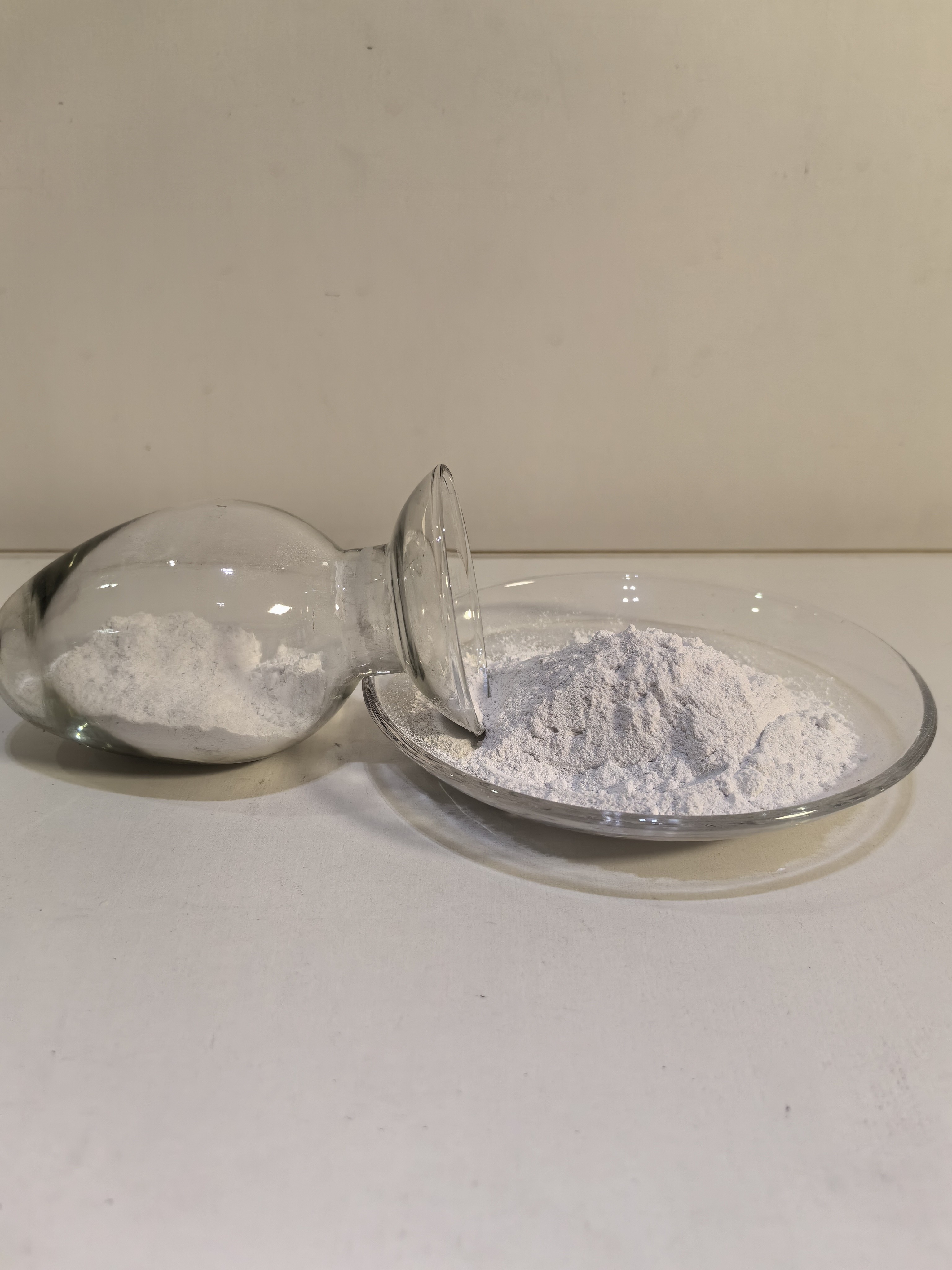

ã€China Aluminum Network】 T5 and T6 are all types of heat treatment. 85% Semi-encrypted Silica Fume 85% Semi-encrypted Silica Fume, is a byproduct of the production of silicon and ferrosilicon alloys. It is a highly reactive pozzolan with a high silica content of over 85% and a bulk density of around 300 kg/m3. The specific surface area of 85% Densified Silica Fume is very high, ranging from 15,000 to 30,000 m2/kg, making it an ideal supplementary cementitious material for enhancing the strength, durability, and workability of concrete. 85% Semi-encrypted Silica Fume, 85% Semi-encrypted Silica Ash, 85% Semi-encrypted Silica Powder Chengdu Rongjian Engineering Materials Co.Ltd , https://www.rjsilicafume.com

T5 is aluminum extrusion from the extruder after cooling with air cooling aluminum to achieve the required hardness (Webster 8 - 12 hardness).

T6 is aluminum extrusion from the extruder after water cooling aluminum temperature, aluminum profiles to achieve higher hardness requirements (Webster 13.5 or more hardness) T5 quenching in the profile plant is generally used air-cooled, T6 in The quenching of the profile plant is generally water-cooled. Both have the same elastic modulus. Under normal circumstances, with the T5 state, if the deflection of the rod passes and the tensile strength is slightly worse, the T6 state can be used. The strength of T6 is better than T5, but T6 is generally higher than T5 by 500-1000 yuan. T5 is usually air-cooled when quenched in a profile plant. T6 is generally water-cooled when quenched in a profile plant. Both have the same elastic modulus. Under normal circumstances, with the T5 state, if the deflection of the rod passes and the tensile strength is slightly worse, the T6 state can be used. The strength of T6 is better than T5, but T6 is generally higher than T5 by 500-1000 yuan.

In addition, T5 is generally used for air-cooling at the quenching of a profile plant. T6 is generally water-cooled at the quenching of a profile plant. Both have the same elastic modulus. Under normal circumstances, with the T5 state, if the deflection of the rod passes and the tensile strength is slightly worse, the T6 state can be used. The strength of T6 is better than T5, but T6 is generally higher than T5 by 500-1000 yuan.

What is the difference between the 6063 aluminum alloy T5 and T6 state

85% Semi-encrypted Silica Fume (85D) is a type of silica fume that has been processed to increase its bulk density. This makes it easier to handle and transport, and can also improve its performance in concrete.