With the development of the automobile industry, the strength of domestic auto companies has gradually increased, as well as the large-scale entry of foreign companies and the improvement of production equipment, the processing of auto parts is developing towards flexible manufacturing. The Flexible Manufacturing System (FMS) brings a high degree of flexibility in processing, enabling a wide range of parts to be produced while maintaining high productivity. This paper introduces the method of operation management and efficiency improvement of the flexible manufacturing FMS production line in the actual production of auto parts.

Introduction to FMS

The flexible manufacturing system is composed of a unified information control system, material storage and transportation system and a set of digital control processing equipment, which can adapt to the automatic mechanical manufacturing system of processing object transformation. FMS is a group of CNC machine tools and other automated process equipment. It consists of a computer information control system and an automatic material storage and transportation system. Simply put, it consists of three subsystems: processing, logistics and information flow.

From the perspective of the composition of FMS, it has both functions of manufacturing and partial production management. From the perspective of flexibility, on the one hand, the ability of the system to adapt to changes in the external environment can be measured by the degree to which the system meets the requirements of the new product; on the other hand, the ability of the system to adapt to internal changes, in the case of interference (such as machine failure), the system The ratio of productivity to productivity expectations in the absence of interference can be used to measure flexibility.

Flexibility is the biggest feature of FMS, mainly in the following aspects:

1) Arrange production in time and reduce lead time.

2) The process is highly concentrated, which can improve equipment utilization.

3) Reduce the direct labor force, and achieve “unmanned production†for 24 hours day and night under the condition of less people.

4) Improve the consistency of product quality.

5) Single fault, the task can transfer other machine tools.

FMS line automatic processing efficiency improvement approach

The idea of ​​improving the efficiency of FMS line is mainly from the "flexibility". Through the analysis of its own characteristics, using the characteristics of running flexibility, process flexibility, process flexibility, through group processing, reducing the first part preparation time, process optimization, etc. To achieve the goal of reducing single-work hours, shortening delivery cycles, increasing labor productivity, and reducing manufacturing costs.

1. Operational flexibility

FMS line single unit failure, can be adjusted to other processing units for manufacturing, blending FMS line machine tool and FMS line combination, separation processing, flexible operation, to achieve the purpose of improving the utilization of each machine. A famous automobile manufacturer's flexible production line for automobile engine block and cylinder head (see Figure 1), the operational flexibility of FMS greatly improves the utilization rate of processing equipment, thereby improving production efficiency.

Figure 1 FMS flexible processing of automotive parts 2. Process flexibility

Due to the high concentration of FMS composites, the system can process a certain family of workpieces in a variety of ways, or to process different types of workpieces simultaneously in a batch production process. This requires optimization of the process to rationalize the process.

In FMS, for automatic machining equipment, the parts must be programmed before machining. However, whether manual programming or automatic programming is used, the formulation of the process route, the selection of the tool, and the determination of the cutting amount must be considered. An important factor in the efficiency of FMS processing.

(1) Process route for multi-variety workpiece processing When formulating the proposed process route, first determine the processing method of each surface, ensure the machining accuracy and surface quality according to the actual conditions of the parts, and then determine the shortest feed route and minimum according to the optimization principle. The number of tool changes to reduce machining assistance time.

(2) Reasonable selection of cutting tools and processing parameters FMS line selection principle: First, material selection, high-quality tools such as cemented carbide or even ultra-fine-grained hard alloy or coating technology are preferred in the automatic processing system. In order to improve the reliability of the use; the second is the tool structure, preferring the machine-clampable indexable structure, or even the composite structure or special-purpose structural tool to reduce the time of tool change, tool setting and sharpening; It is preferred to use standardized or serialized shank and use a short shank as much as possible to increase the rigidity of the tool.

3. Process flexibility

The use of the FMS line group processing method enables efficient use of the production line and avoids waste of running time and processing time. The group processing method refers to the processing method in which a plurality of parts of the same or different parts are integrated by the jig, the process is reasonably arranged, and the plurality of parts are completed in the tray once into the machine tool. Group processing in the machining center series can be divided into group processing of the same parts and group processing of different parts.

Compared with single-piece production, the advantages of group processing are: reducing the number of tool changes and the empty feed per unit program running; the tool processing path is optimized, and the working time of the single-piece machining is shortened; the automatic running time is extended, It is convenient to realize unmanned processing; reduce the auxiliary time of the operator, the number of pallet exchanges, the number of runs of the trolley, and reduce the mechanical loss. However, there are also disadvantages: if there is a problem, it will cause a bad batch.

Taking the processing of the cylinder block, the cylinder head and the bearing cap of the automobile as an example, as shown in Fig. 2, the total number of processes required for the conventional process is 64, and the total number of processes required for the FMS system is 12, and only one is required. The complete machining unit of the engine can complete all the processes of the engine cylinder head bearing cap. It can be seen that the FMS process is highly intensive, the equipment is modularized, the equipment investment is reduced, and the product quality is improved. At the same time, the equipment can be configured according to the increase or decrease of market demand, which has very high flexibility and is the best system that can quickly respond to market trends. When the market develops rapidly, using FMS to produce efficiently, it can increase market share, and can also transform products according to market trends, and not produce excess inventory to improve capital turnover.

Figure 2 Comparison of traditional processing technology and FMS group processing 4. Quality management

Flexible manufacturing FMS can achieve high production efficiency, and quality management control is particularly important. Practice has proved that the quality control of manufacturing qualified parts requires a stable process system, standardized operation process, constant temperature monitoring, stable processing equipment, tool life management and necessary self-test.

5. Improvement of the comprehensive skills of the operators

The improvement of the operator's comprehensive skills is also a key factor in improving efficiency. The operator needs to have the ability to plan the arrangement of the machine tools on the FMS production line. Pay attention to the following points: the machine is in the automatic processing state during the normal operation; all the pallets are waiting for processing, and the machine will not have no material to be processed; The plan is reasonably arranged and the personnel are matched to realize the unmanned operation of one shift; the situation of achieving the minimum number of operators and single machine operation of multiple machine tools.

Conclusion

FMS brings a high degree of flexibility in processing, modularization of its open structure and flexible structure technology, and further improvement in cutting speed and precision of the machining center, which has won better benefits for the automotive industry and its application in future automobile production. It will be more and more extensive.

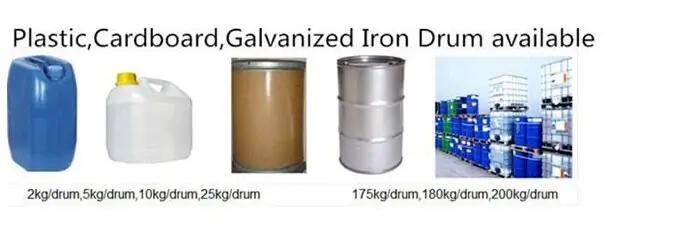

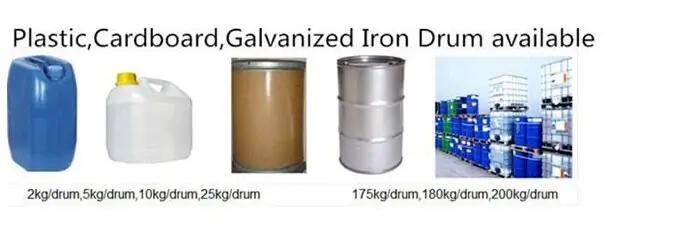

Body Care Essential Oil

We provide kinds of body care essential oil,such as,Body shaper,Weight Loss,Slimming,acne scar removal and acne treatment essential oil blend,Reduce stress,calm relaxing,Anti-Axiety,SPA Relieve pain,Foot massage,Special treatments for shoulder and neck,Nursing care of uterus and ovary,Elmination of toxicant and beauty care,Massage Oil for muscle relief,Scraping Detoxification Essential Oil,Varicose vein,Endocrine regulation,Endocrine dyscrasia,Eliminate/Remove stretch marks,firming skin,Relieve (menstrual) menstruation pain.

Massage oil for weight loss,slimming essential oil

Help the body burn fat,make the body in good style.

Small Bottle Packing:10ml,20ml,30ml,50ml,100ml

Bulk packaging:1kg,5kgs,10kgs,25kgs,175kgs in a drum

Other compound essentials oils as below.

|

Moisturizing to the skin

|

Eye Care and Soothing

|

acne scar removal and acne treatment essential oil blend

|

|

Remove redblood

|

Anti-wrinkle and eye dark circle removal

|

blackspot purified/blackspot removal

|

|

Skin whitening

|

SPA Relieve pain

|

Wrinkle removal and tender-skin

|

|

Foot massage

|

Shrink skin pores

|

Reduce stress,calm relaxing,Anti-Axiety

|

|

Antibacterial anti-inflammatory,acne removal

|

Special treatments for shoulder and neck

|

Nursing care of uterus and ovary

|

|

Elmination of toxicant and beauty care

|

Massage Oil for muscle relief

|

Scraping detoxification essential oil

|

Shipping method: By sea to your closed sea port, by air to your closed international air port, by expresss couriers,such

as,Fedex to your door.

Delivery: ex works around 2-3 working days for not big quantity

FAQ

Q:How to get a sample,will you supply free sample ?

We will accept sample order,small quantity to start,we will accept some sample free,but

the shipping cost is at your side.

Q: What is your payment method?

Our payment term is T/T advance to our company bank account,small amount can be Western Union

Q: Can you accept OEM/ODM ?

Yes, We can specially make the products for you,your demanded logo,package,etc.

Q: How about the products shelf life?

2-3 years

Q:How long I can get the order ?

Sample or small quantity is ex works around 2-3 working days

Bulk big quantity usually need 7-10 days ex works

Please contact us for more details

Body Care Essential Oil

Ylang Oil,Body Care Essential Oil,Scraping Detoxification Essential Oil,Body Sculpting Essential Oil

Jiangxi Global Natural Spice Co., Ltd. , https://www.chessentialoil.com